main

Environmental Equipment

Fume Collectors

Welding Fumeresa ( FRM-H15B )

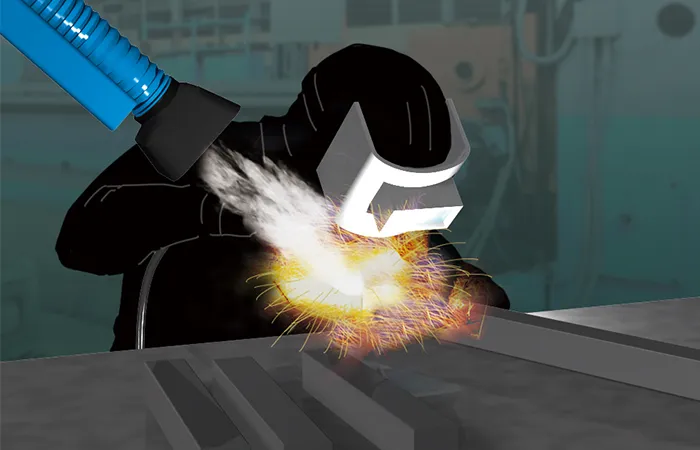

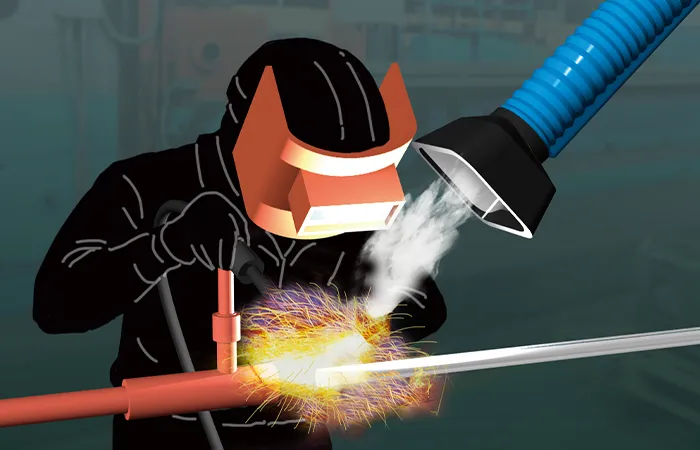

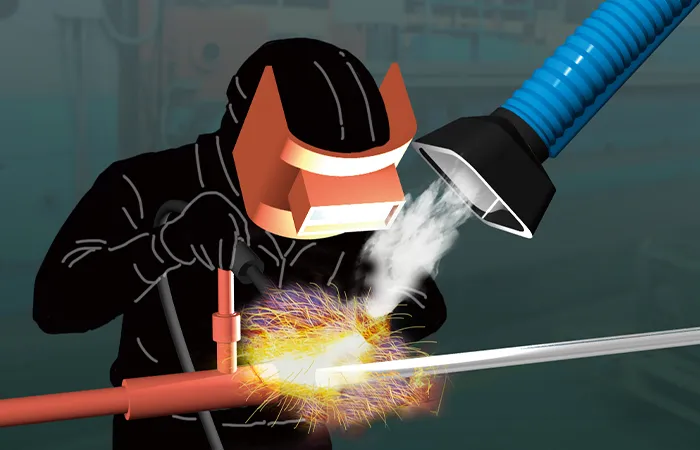

The Fumeresa (FRM-H15B) is a fume extraction unit designed to efficiently capture hazardous fumes generated during welding operations, improving workplace safety and comfort. With a high-capacity airflow of 30 m³/min, it provides powerful suction across a wide area, efficiently capturing both fumes and dust. It delivers outstanding collection performance in metal welding environments.

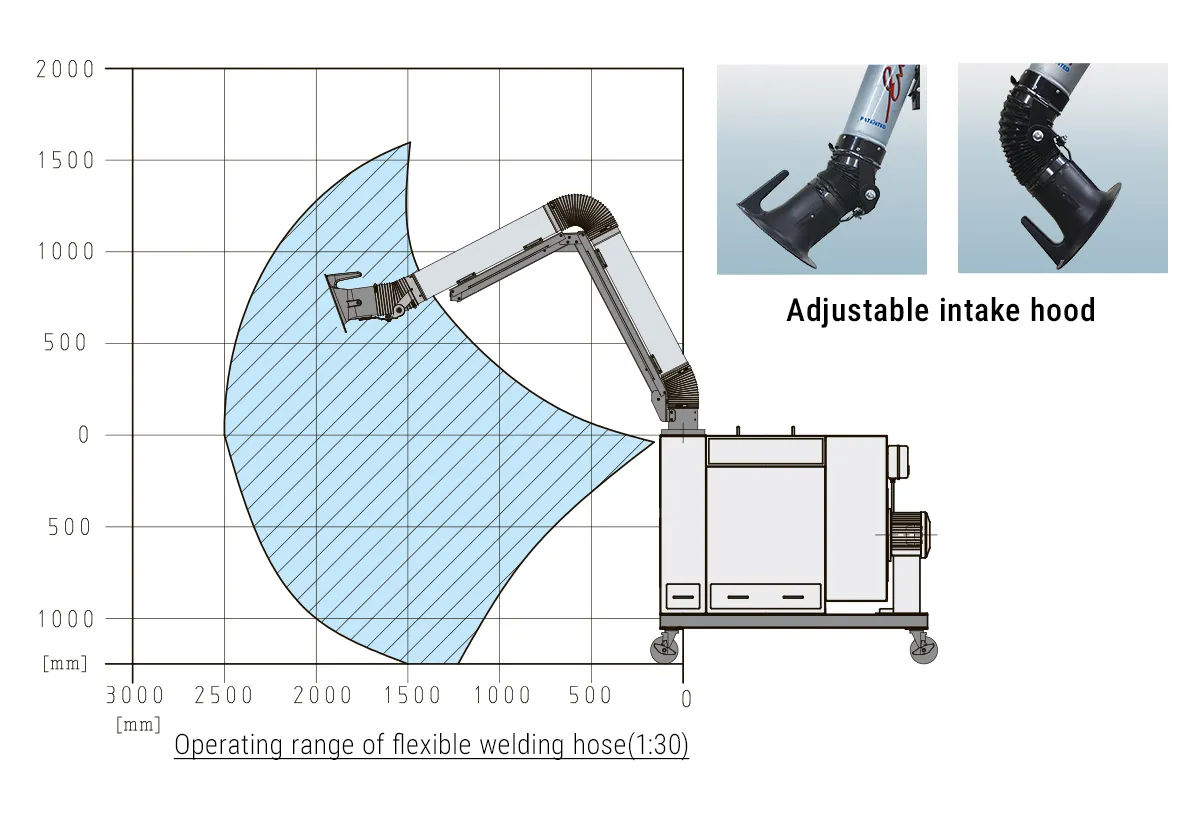

The unit is equipped with a suction arm from CORAL (Italy), featuring three articulated joints and a 360-degree rotatable mechanism. This allows the intake hood to be flexibly positioned close to the fume source, enabling efficient fume collection tailored to various working conditions.

PDF documentation and CAD data for this product are available for download.

※ Unpack ZIP packages to view the content. The content may consist of PDF or CAD data.

※ CAD data is in dxf format. Use a specialized CAD application or similar to view the file.

※ The performance curve diagram may have an error margin of approximately -5% to +10%.

-

Product Flyers

-

Manuals

-

External Dimensions

Drawings PDF -

External Dimensions

Drawings CAD -

Please contact us regarding other documentation

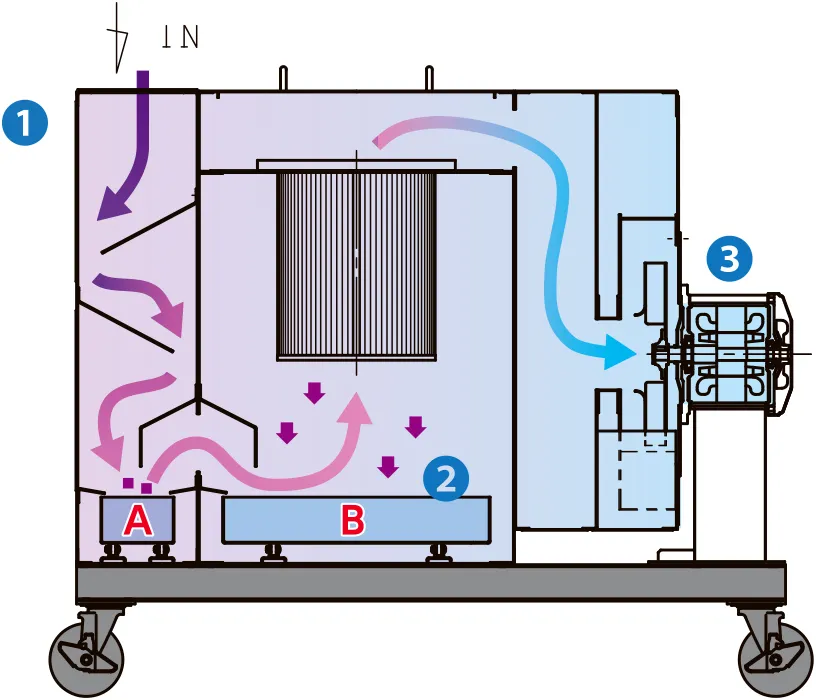

Structure

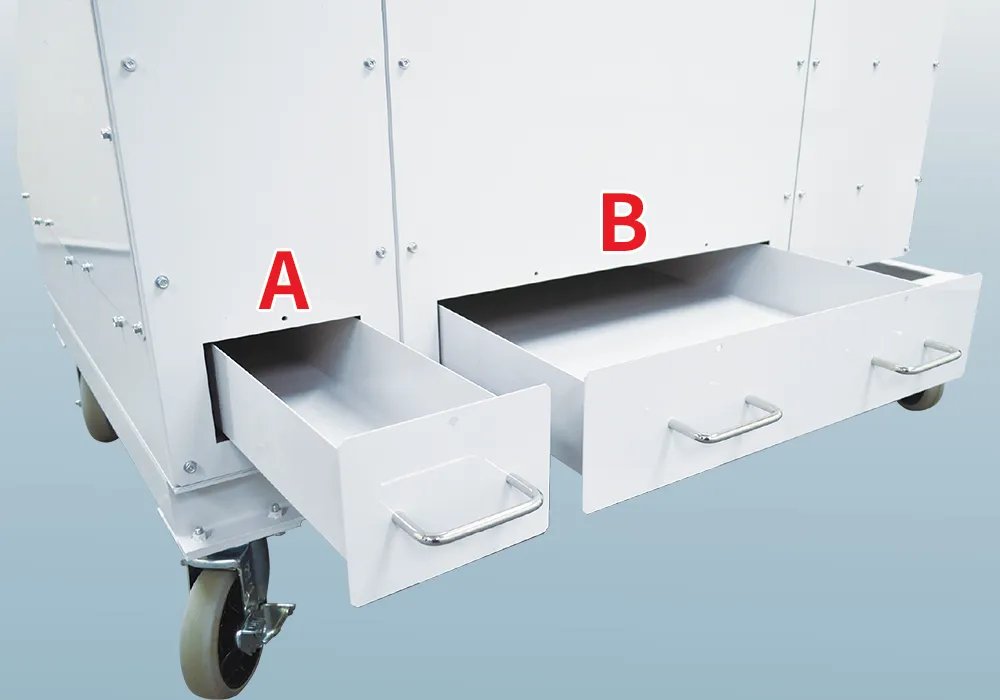

- 1. The dust-laden air is drawn in and passes through a vertically descending channel, where heavier dust particles are collected in Dust Box A.

- 2. The remaining fine dust is filtered, and the separated particles accumulate in Dust Box B.

- 3. The cleaned air is discharged from the back of the unit through the blower.

Features

-

Powerful suction with high airflow of 30 m³/min

Effectively captures welding fumes across a wide area with excellent dust collection performance.

-

High-performance intake arm by CORAL (Italy)

Features three articulated joints and a 360° rotatable structure for flexible positioning near the fume source.

- Equipped with casters for easy relocation within the workspace

-

Ideal for metal welding applications

Captures harmful fumes to ensure worker safety and maintain a comfortable working environment.

Applications

Arc welding operations / Spot welding operations / Laser welding and laser cutting operations / Robotic welding lines / Indoor compact welding booths / Repair and maintenance work

Operating range of flexible welding hose

Specifications

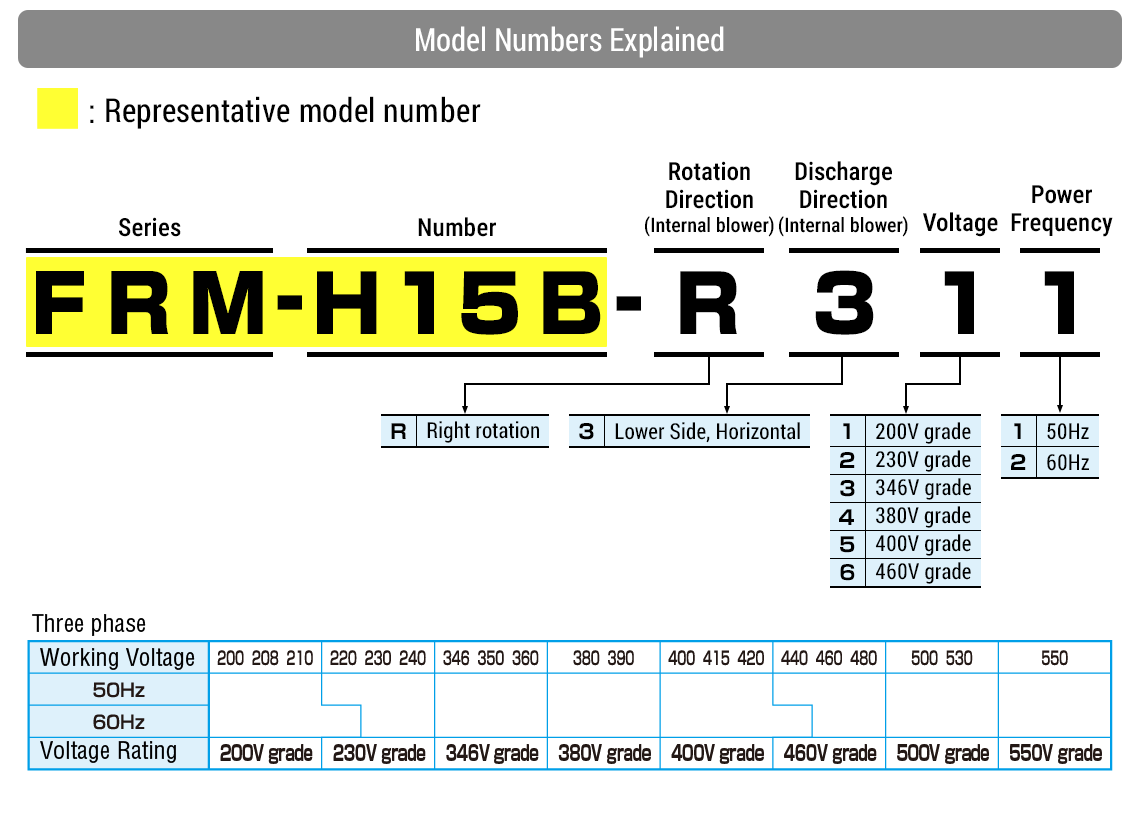

Model explained

| Model | FRM-H15B |

|---|---|

| Power Supply | 3 Phase 50/60Hz |

| Motors | 1.5kW/2P |

| Voltage | 50Hz: 200V 60Hz: 200V/220V |

| Maximum Airflow | 30 m3/min |

| Intake Airflow Speed | 17 m/s |

| Noise level | 79 dB(A) (1 meter from the unit) |

| Weight | 376 kg |

| Filter | 2 molded filters (cellulose) |

Expendables

| Item Name | Model | Qty | Product Code |

|---|---|---|---|

| Intake Duct | 3FRD-H15B | 1 | 10014953 |

| Filter *1 | 3FRF-H15B | 2 | 10014959 |

*1 The recommended filter replacement interval is every 6 months to 1 year. Replacement timing may vary depending on the customer's usage conditions.

A Bit of Engineering When You're in a Bind

SDG will totally support activities ranging from measurement of welding fume concentration to selection and construction of necessary ventilation and dust collection equipment.

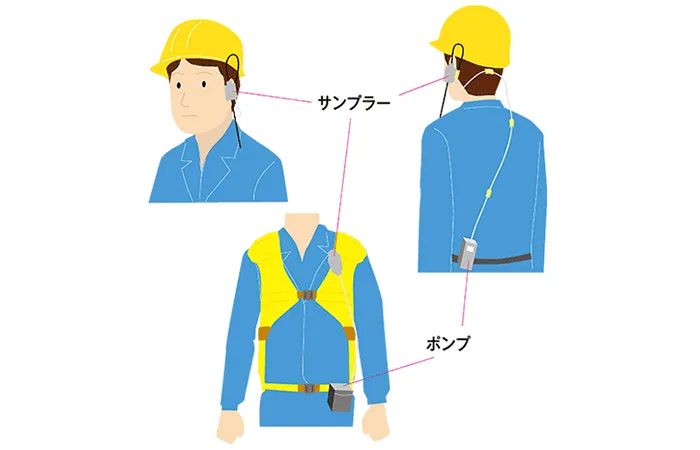

Measurement of personal exposure

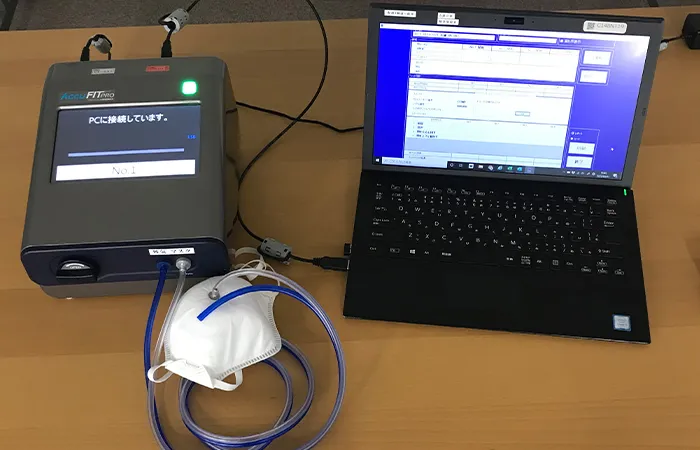

Evaluating Respirators

Airflow Analysis

(To be visible)

(To be visible)

Welding Fume Control Solutions

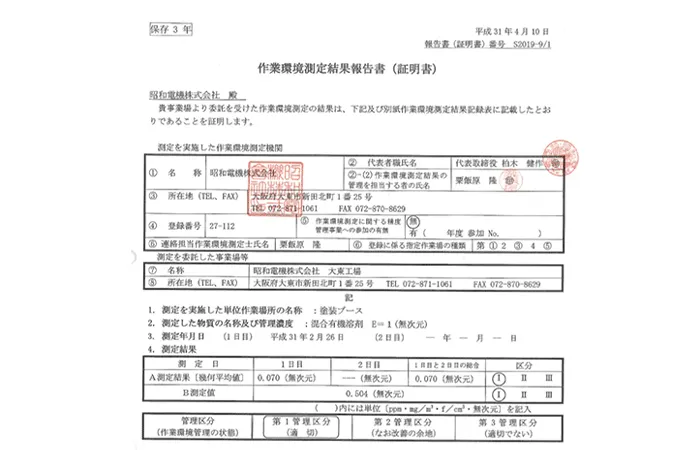

Working environment measurementresult report (Certificate)

-

Ordinance on Prevention of Hazards Due to Specified Chemical Substances

Strengthening of measures for preventing health impairment at welding shopsAmendment of Ordinance on Prevention of Hazards Due to

Strengthening of measures for preventing health impairment at welding shopsAmendment of Ordinance on Prevention of Hazards Due to

Specified Chemical Substances -

Little bit Engineering of SDGService of SDG

Product contacts

Use this form to request a quote for this product, as well as submit product and technology questions, malfunction and repairs questions, and other general inquiries.

Contact us