main

Environmental Equipment

Mist Collectors

Mistresa Multi-select Type ( CRM )

The CRM model is a mist collector that can be configured with either a filter type or a demister (filterless) type, depending on the application—whether water-soluble or oil-based coolant is used. Compared to previous models, it offers improved maintainability, allowing tool-free filter replacement and significantly reducing maintenance time. With simple “open, replace, and close” operation, maintenance is smooth and efficient.

For details, see our online catalog.

Online Catalog

PDF documentation and CAD data for this product are available for download.

※ Unpack ZIP packages to view the content. The content may consist of PDF or CAD data.

※ CAD data is in dxf format. Use a specialized CAD application or similar to view the file.

※ The performance curve diagram may have an error range of approximately -5% to +10%.

-

General Catalogs

-

Produci Flyers

-

Manuals

-

Performance

Curves-

SCROLL or SWYPE

-

CRM-H02D (50Hz)

-

CRM-H02D (60Hz)

-

CRM-H02F (50Hz)

-

CRM-H02F (60Hz)

-

CRM-H04D (50Hz)

-

CRM-H04D (60Hz)

-

CRM-H04F (50Hz)

-

CRM-H04F (60Hz)

-

CRM-H07D (50Hz)

-

CRM-H07D (60Hz)

-

CRM-H07F (50Hz)

-

CRM-H07F (60Hz)

-

CRM-H15D (50Hz)

-

CRM-H15D (60Hz)

-

CRM-H15F (50Hz)

-

CRM-H15F (60Hz)

-

CRM-H22D (50Hz)

-

CRM-H22D (60Hz)

-

CRM-H22F (50Hz)

-

CRM-H22F (60Hz)

-

SCROLL or SWYPE

-

-

External Dimensions

Drawings PDF -

External Dimensions

Drawings CAD -

Please contact us regarding other documentation

Features

- 1. Filter or Demister type

- Choose between a filter or a demister (filterless) option based on your usage environment.

-

LEARN MORE

- 2. Simple, safe maintenance

- The filter or demister can be changed while the duct hose is still attached.

-

-

Single-hinged lid: The lid is also removable! -

One-touch filter replacement!

-

- 3. Motor with burnout protection terminal

- A thermal protector is attached to the motor coil, and this is connected to the operating circuit of the electromagnetic switch in order to prevent burnout.

- 4. Excellent motor

- Our safe designs use IP65-grade protection (dust resistance, sprayed water protection models).

- 5. Includes our own manufactured top runner motor IE3

- 0.2kW、0.4kW excluded

- 6. CE compatible

- At customer request, we can build CE specification products.

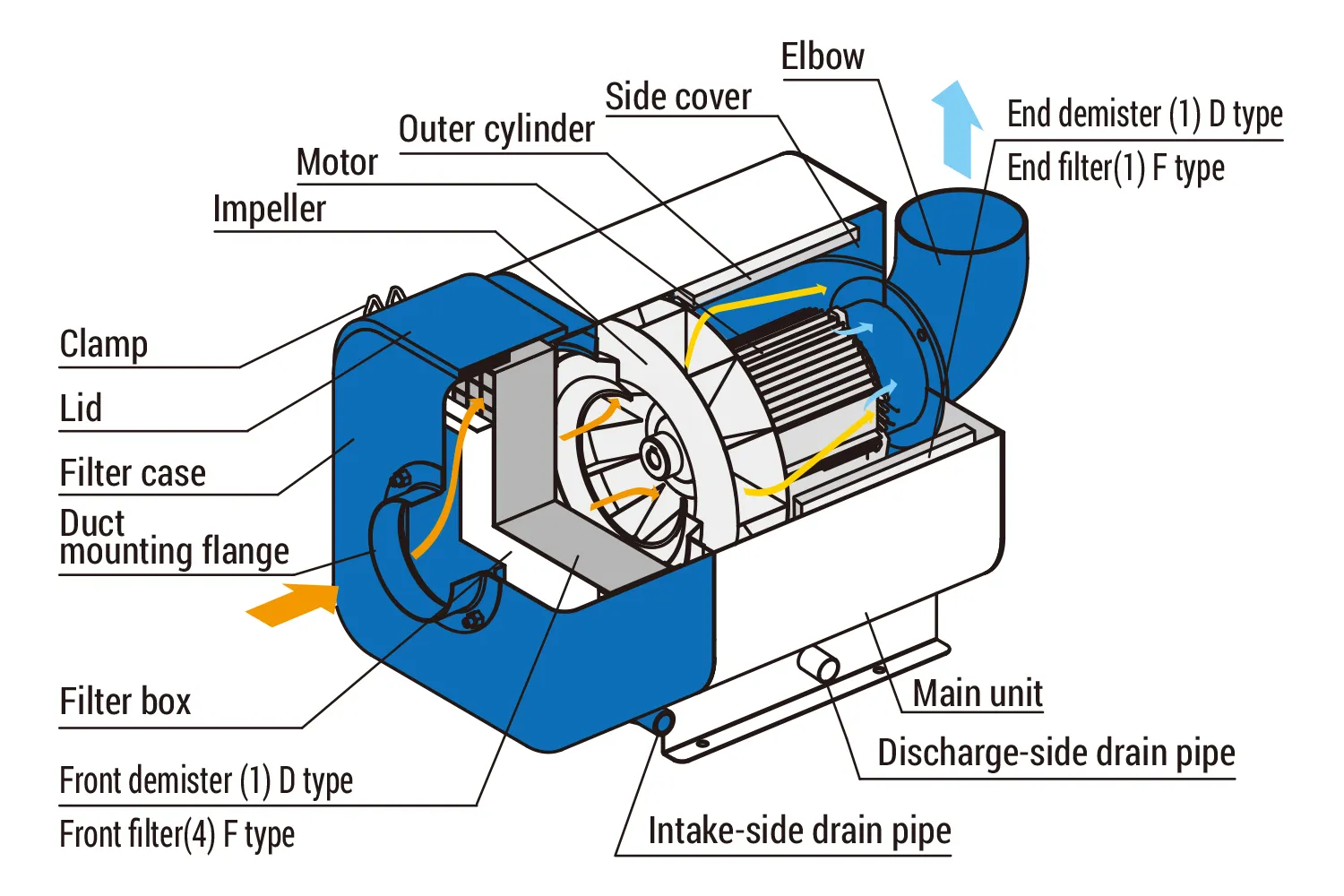

Internal structure

- Front Demister

-

Suctioned air containing mist hits the collision plate, and the mist drops down and forms droplets. These large mist droplets adhere to the front demister and are discharged through the drain.

(Mainly compatible with water-soluble cutting fluids)

- End Demister

-

Fine mist particles pass through the front, adhere to the end demister, and are discharged via the drain.

(Mainly compatible with water-soluble cutting fluids)

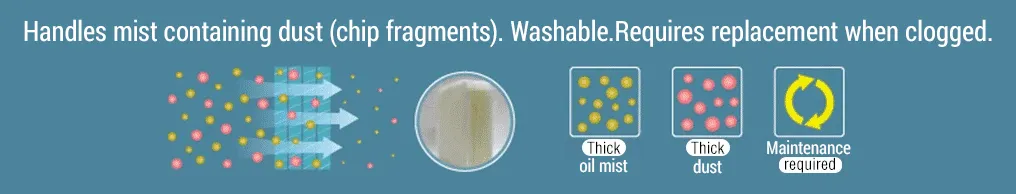

- Front Filter

-

Suctioned air containing mist hits the collision plate, and the mist drops down and forms droplets. These large mist droplets adhere to the front filter and are discharged through the drain.

(Mainly compatible with oil-based cutting fluids)

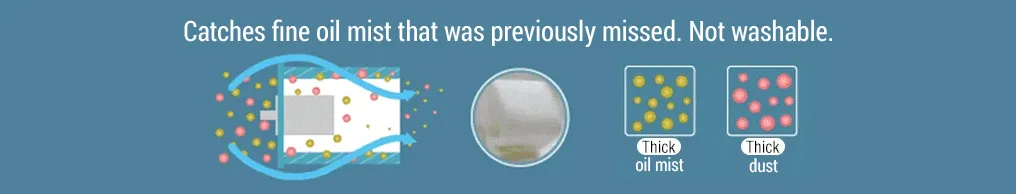

- End Filter

-

Fine mist particles pass through the front, adhere to the end filter, and are discharged via the drain.

(Mainly compatible with oil-based cutting fluids)

Applications

Machine tools / NC lathes / General-purpose lathes / Cylindrical grinders / Inner-surface grinders / Centerless grinders / Millers / Machining centers / EDM machinery / Die casting machinery / Other (machinery that generates mist)

Suitable for applications other than those listed above. Please feel free to let us know your own requirements.

Specifications

Standard Specifications

Model explained

| Model ( → Model explained ) | CRM-H02□ | CRM-H04□ | CRM-H07□ | CRM-H15□ | CRM-H22□ |

|---|---|---|---|---|---|

| Power Supply | Three phase 50Hz200V 60Hz200V/220V | ||||

| Output (kW) | 0.2 | 0.4 | 0.75 | 1.5 | 2.2 |

| Heat-resistant class | 155 (F) | 130 (B) | 130 (B) | 155 (F) | 155 (F) |

| Frequency (Hz) | 50/60/60 | ||||

| Current (A) | 1.6/1.3/1.3 | 2.0/2.0/2.0 | 3.0/3.3/3.3 | 6.9/7.0/7.0 | 10.2/10.4/10.4 |

| Weight (kg) | 27 | 33 | 43 | 67 | 78 |

| Intake Port Diameter (mm) | ∅98 | ∅98 | ∅123 | ∅148 | ∅198 |

| Ambient Temperature (℃) | 0 to 50 | ||||

| Maximum Intake Temperature (℃) | 50 | ||||

Specifications by Type

| Model | 50Hz | 60Hz | Collection Efficiency (%) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Maximum Airflow (m3/min) |

Maximum Static Pressure (kPa) |

Noise Level 1mdB(A) |

Power consumption (kW) |

Maximum Airflow (m3/min) |

Maximum Static Pressure (kPa) |

Noise Level 1mdB(A) |

Power consumption (kW) |

||

| CRM-H02D | 5.4 | 0.55 | 64 | 0.21 | 6.2 | 0.80 | 67 | 0.27 | 99.2 |

| CRM-H02F | 4.3 | 0.50 | 57 | 0.19 | 5.1 | 0.70 | 62 | 0.24 | 99.8 |

| CRM-H04D | 6.0 | 0.75 | 68 | 0.26 | 7.0 | 1.10 | 72 | 0.40 | 99.2 |

| CRM-H04F | 4.6 | 0.70 | 63 | 0.22 | 5.6 | 1.00 | 67 | 0.33 | 99.8 |

| CRM-H07D | 10 | 1.10 | 73 | 0.56 | 12 | 1.60 | 78 | 0.92 | 99.2 |

| CRM-H07F | 7.6 | 1.05 | 69 | 0.47 | 9.2 | 1.50 | 76 | 0.77 | 99.8 |

| CRM-H15D | 18 | 1.60 | 81 | 1.35 | 21.5 | 2.30 | 83 | 2.24 | 99.2 |

| CRM-H15F | 14.5 | 1.50 | 74 | 1.16 | 17.5 | 2.15 | 77 | 1.90 | 99.8 |

| CRM-H22D | 24.5 | 1.70 | 83 | 1.93 | 28.5 | 2.40 | 86 | 3.13 | 99.2 |

| CRM-H22F | 18 | 1.55 | 76 | 1.54 | 21 | 2.25 | 79 | 2.44 | 99.8 |

Accessories

| Drain tube 2.5m x 2 | ○ |

|---|---|

| Hose band (for drain tube) x 2 | ○ |

| Vibration damping pad x 4 | ○ |

| Duct mounting flange※ x 1 | ○ |

| Crimp-style terminal x 7 (1 spare) | ○ |

※ One duct mounting flange is required for installing the product. We also provide another one for installation on the paired device. Also note that in the CRM series, the gasket (for the duct mounting flange) is glued onto the duct mouting flange.

Filters

| Mistresa Model | Compatible Type | Compatible Model | Replacement Guideline | Washable |

|---|---|---|---|---|

| CRM-H02F | Front Filter | 3KFF-H04S | 1 - 6 months | ○ |

| End Filter | 3KEF-H04F | 6 - 12 months | × | |

| CRM-H02D | Front Demister | 3KFD-H04S | 12 - 24 months | ○ |

| End Demister | 3KED-H04D | 24 - 36 months | ○ | |

| CRM-H04F | Front Filter | 3KFF-H04S | 1 - 6 months | ○ |

| End Filter | 3KEF-H04F | 6 - 12 months | × | |

| CRM-H04D | Front Demister | 3KFD-H04S | 12 - 24 months | ○ |

| End Demister | 3KED-H04D | 24 - 36 months | ○ | |

| CRM-H07F | Front Filter | 3KFF-H07S | 1 - 6 months | ○ |

| End Filter | 3KEF-H07F | 6 - 12 months | × | |

| CRM-H07D | Front Demister | 3KFD-H07S | 12 - 24 months | ○ |

| End Demister | 3KED-H07D | 24 - 36 months | ○ | |

| CRM-H15F | Front Filter | 3KFF-H15S | 1 - 6 months | ○ |

| End Filter | 3KEF-H15F | 6 - 12 months | × | |

| CRM-H15D | Front Demister | 3KFD-H15S | 12 - 24 months | ○ |

| End Demister | 3KED-H15D | 24 - 36 months | ○ | |

| CRM-H22F | Front Filter | 3KFF-H22S | 1 - 6 months | ○ |

| End Filter | 3KEF-H22F | 6 - 12 months | × | |

| CRM-H22D | Front Demister | 3KFD-H22S | 12 - 24 months | ○ |

| End Demister | 3KED-H22D | 24 - 36 months | ○ |

Options

We offer a wide array of options so you can optimize your setup.

About Piping

- 1.Duct hose material

- Duct hose lifespan is affected by the type of mist being suctioned. We recommend oil-resistant duct hoses.

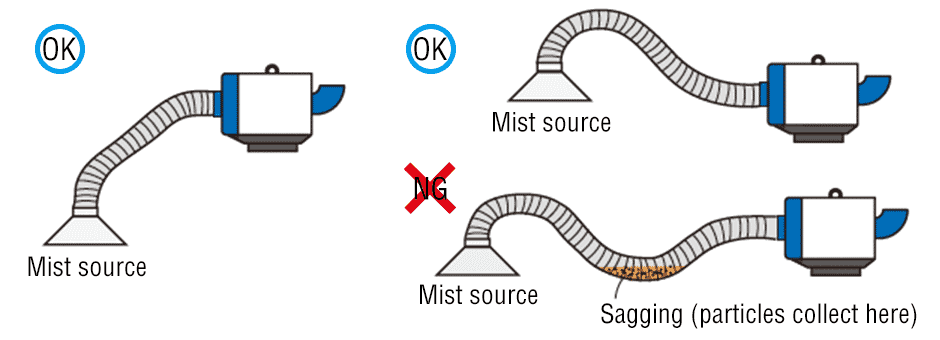

- 2. Intake duct piping

- ① Use easy-to-maintain, vibration damping flexible ducts (optional part).

- ② When laying out ducts, ensure there is an adequate length without downward sagging.

- ③ For easy mating of ducts, use duct mounting flanges (accessory).

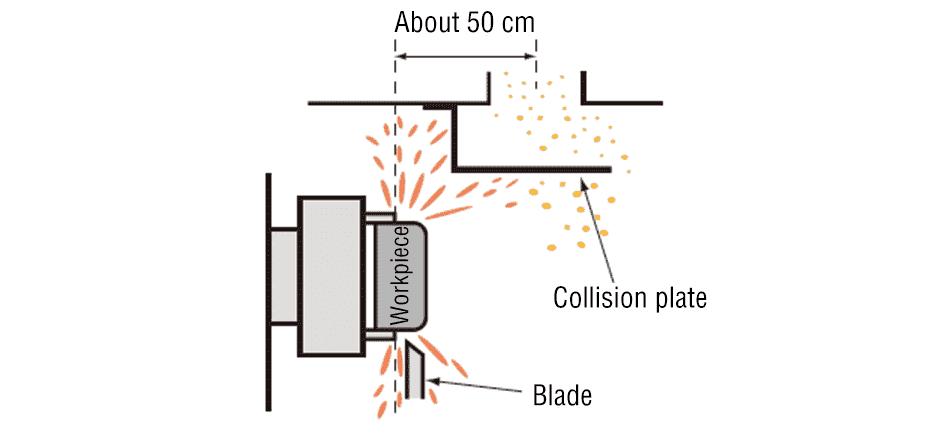

- ④ When the intake port is placed close to the mist source, large quantities of mist, chips, and dust are suctioning into the machine. This can cause overspill leaks and clogging of the filter and demister. Move the intake port a short distance from the source (about 500 mm), or use a collision plate to prevent overspill leaks and the clogging of the filter or demister.

- 3. Drain tube piping

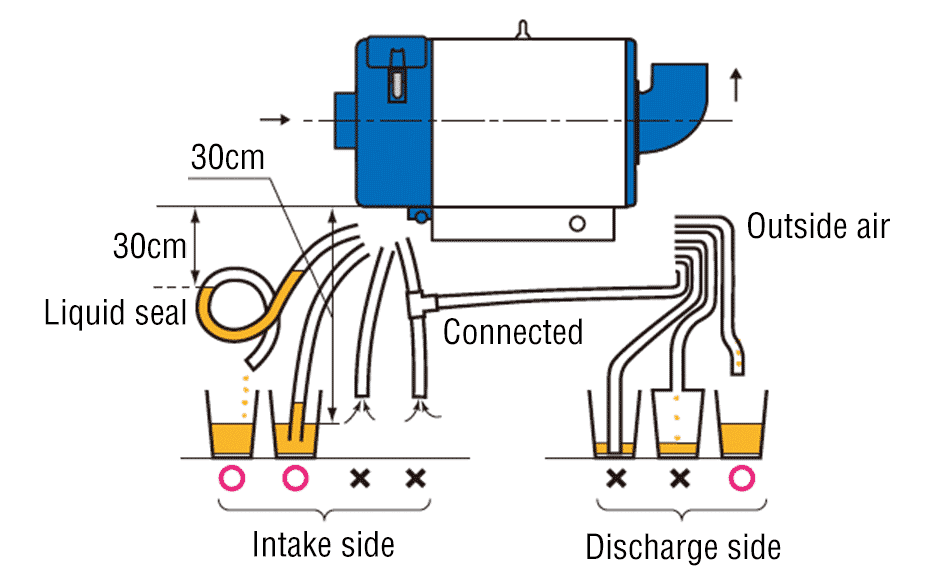

- ① Always use a liquid seal on the intake side. (Failure to use a liquid seal will cause air to be drawn in via the end of the drain tube and cause a reverse airflow that will prevent discharge. This forces the airflow to the next filter and thus speeding up clogging.)

- ② Do not connect the intake-side and discharge-side drain tubes.

- ③ Be sure to leave the discharge side open to the outside air. (If the drain tube is not open to the outside air, discharge will be impaired and the contents may instead accumulate inside the main unit.)

- ④ Drain pipes not connecting drain tubes should be sealed with a plug or similar.

For Your Safety

- ● Do not install in dangerous locations

- The Mistresa is not built as a pressure-resisting, explosion-proof device. When operated in locations with explosive gases present, motor burnout may ignite the gases, causing an explosion.

- ● To avoid fires and explosions

- Do not attempt to suck up explosive gases, organic solvents, or flames.

- ● To avoid fires and electric shock

- Mistresa wiring installation must be performed by a qualified electrician in accordance with electrical equipment technical standards and internal wiring regulations.

- ● Do not perform maintenance/inspections while operating

- All fans should be stopped before attempting to replace filters or perform inspections.

Product contacts

Use this form to request a quote for this product, as well as submit product and technology questions, malfunction and repairs questions, and other general inquiries.

Contact us